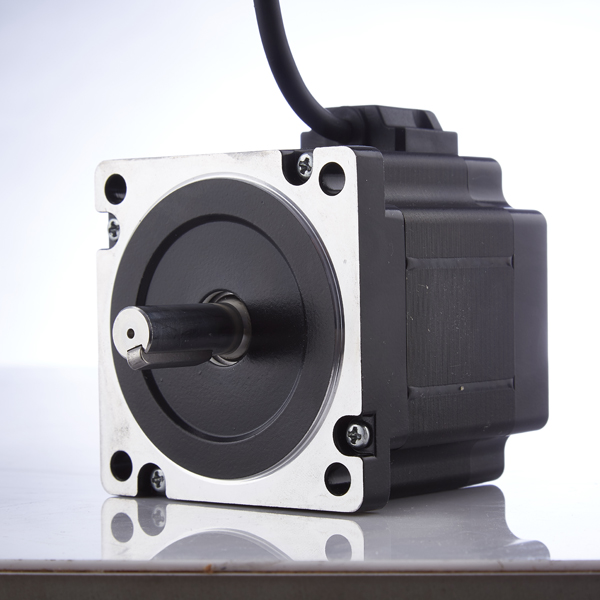

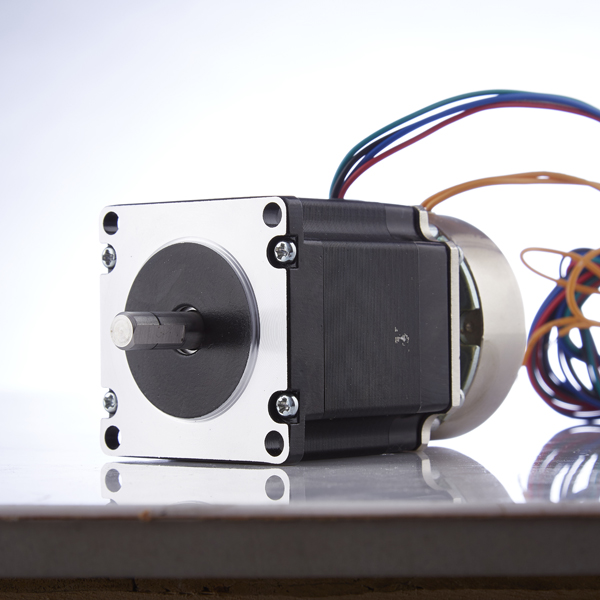

Stepper motors are widely used in 3D printers, and their high precision, stability, and relatively low cost make them common driving components in 3D printers. The following are the specific applications and advantages of stepper motors in 3D printers:

1、 Precise control positioning

Stepper motors control their rotation angle by receiving pulse signals, with each pulse corresponding to a fixed step angle, thus achieving precise position control. In 3D printers, stepper motors are used to drive the movement of the print head and construction platform, ensuring precise positioning during the printing process. This precise control is crucial for ensuring the dimensional accuracy and surface quality of printed materials< br>

2、 Low cost and easy to maintain

Compared to other types of motors such as servo motors, stepper motors have lower costs, which is an important consideration for 3D printers with lower manufacturing costs. In addition, the structure of stepper motors is relatively simple, and maintenance and replacement are also relatively easy, reducing the user's operating costs< br>

3、 High stability and reliability

Stepper motors have high stability and reliability during operation, and are not easily affected by external interference. This enables the stepper motor to run stably for a long time in 3D printers, reducing failure rates and improving printing efficiency< br>

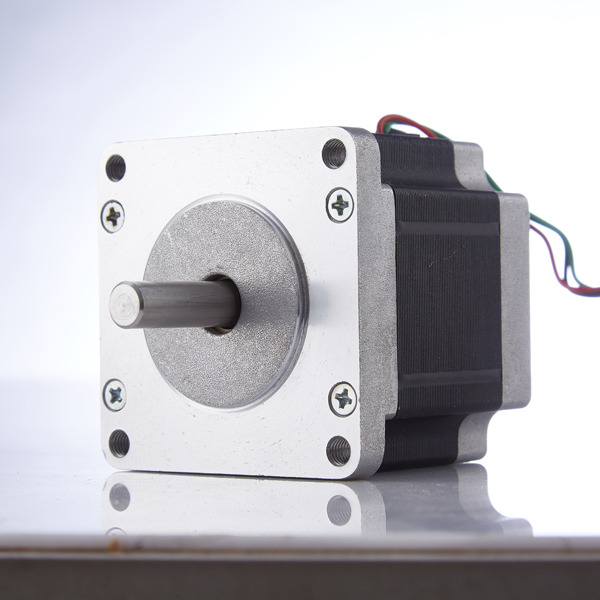

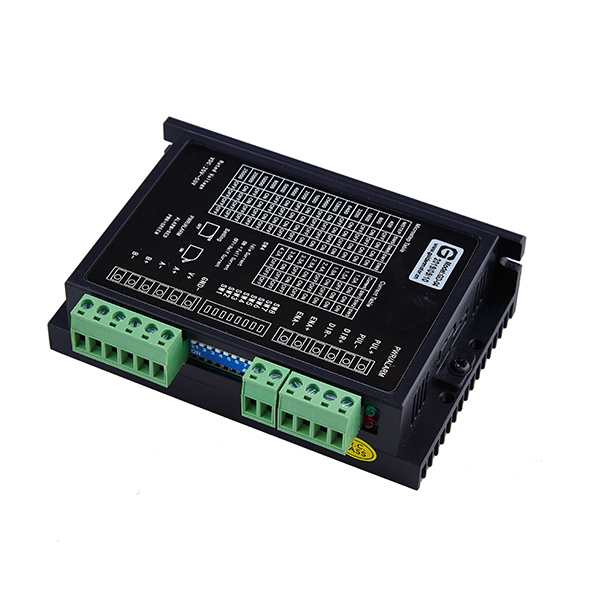

4、 Subdivision technology improves accuracy

In order to further improve the control accuracy of stepper motors, subdivision technology is often used in 3D printers. Subdivision technology achieves finer control by increasing the number of steps of the stepper motor, making the angle corresponding to each pulse smaller. For example, a stepper motor with a step angle of 1.8 °, after using 16 subdivisions, the angle corresponding to each pulse will become 0.1125 °, greatly improving control accuracy< br>

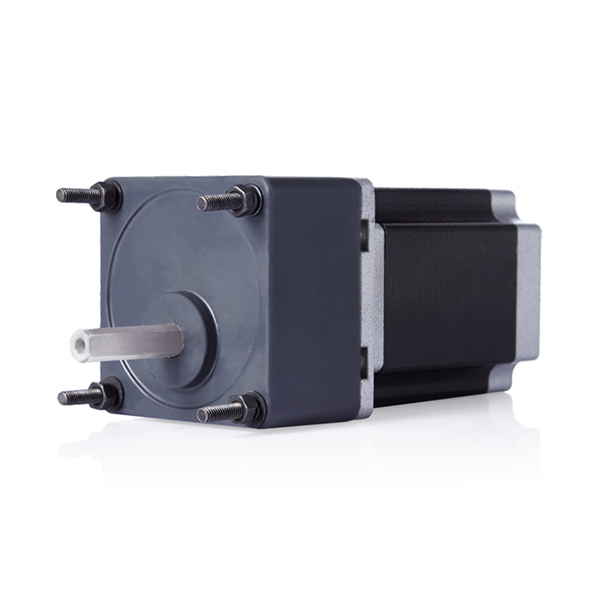

5、 Reduce vibration and noise

Stepper motors may generate vibration and noise during operation, which can affect the printing quality of 3D printers. In order to reduce vibration and noise, some high-end 3D printers adopt advanced driver chips and control algorithms, such as Trinamic's TMC2208 driver chip, which reduces vibration and noise and improves print quality by accurately controlling current and micro stepper< br>