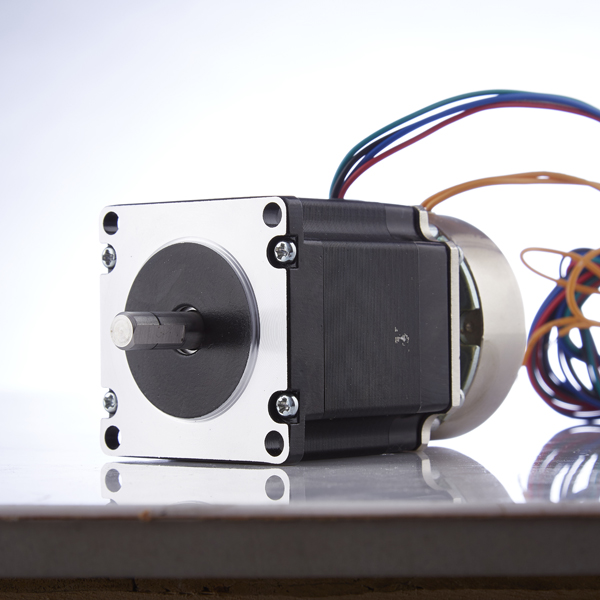

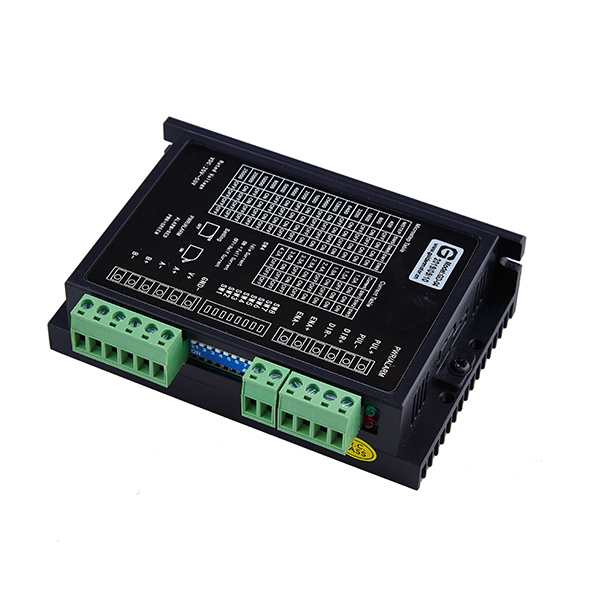

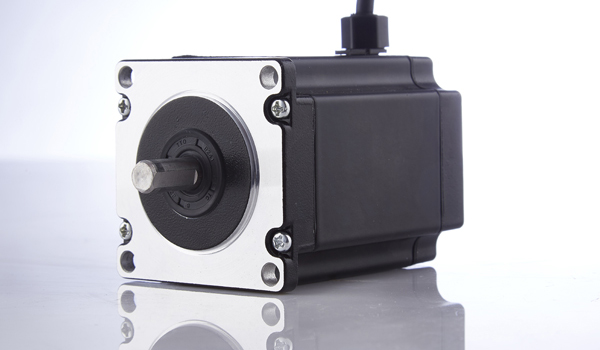

What are the applications of stepper motors in packaging machinery? Below, we will introduce several application examples of stepper motors in packaging machinery and point out the broad application prospects of stepper motors in packaging machinery.

The application of stepper motors in the supply of packaging film, such as in packaging machines that integrate bag making, filling, and sealing, requires plastic film positioning and fixed length supply for packaging. Whether intermittent or continuous supply, stepper motors can be reliably used to complete it.

Stepper motors are used in intermittent packaging machines, which use stepper motors to supply film and improve reliability. In the past, the supply of packaging film often used the intermittent pulling method of crank connecting rod mechanism, which had a complex structure and difficult adjustment. Especially when it was necessary to replace the product, not only was it difficult to adjust, but also a lot of packaging film was wasted. The use of a stepper motor directly connected to the tension roller not only simplifies the structure, but also makes adjustment extremely convenient. It can be achieved through buttons on the control panel, saving both adjustment time and packaging materials.

In intermittent packaging machines, there are two modes for controlling the supply of packaging materials: bag length control mode and color code control mode. The bag length control mode is suitable for packaging films without color codes. It is achieved by pre-set the speed of the stepper motor, and the setting of the air ratio can be achieved through a dial switch. The color code mode is equipped with a photoelectric switch, which detects the position of the color code. When the color code is detected, a control switch signal is sent out. After the stepper motor presses the signal, it stops rotating and delays for a certain period of time before rotating the film supply again, repeating the cycle to ensure that the film is supplied according to the position of the color code for a fixed length.

That's all for the introduction in this chapter. In the next chapter, we will continue to look at the application of stepper motors in continuous packaging machines.