Eccentric shaft gear motor, as an innovation in the field of mechanical transmission, realizes non-concentric transmission through eccentric shaft structure, breaking through the design limitations of traditional gear reducer. Its core advantage is that it converts rotational motion into compound eccentric motion, increasing torque output while reducing speed, especially for industrial scenarios requiring high precision, low noise, and compact construction.

First, technical principle and structural characteristics

1.Eccentric shaft drive mechanism

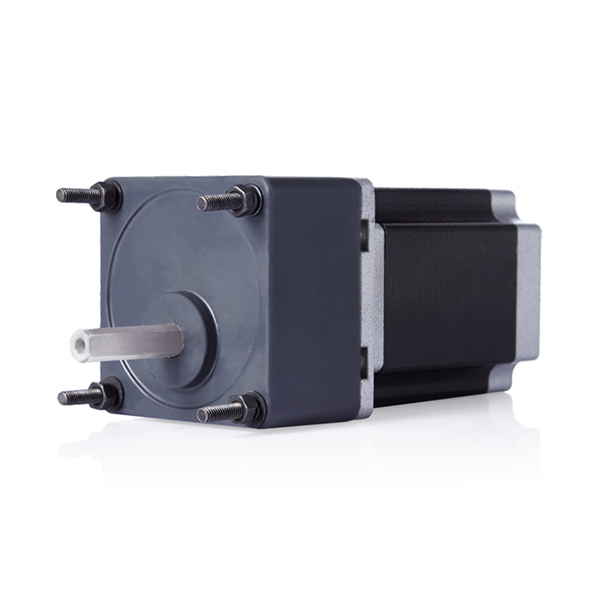

The core of eccentric shaft reducer is eccentric shaft design, which has a fixed offset between the axis and the rotation center. When the input shaft rotates, the eccentric shaft drives the gear group to produce non-concentric motion, and the deceleration is achieved through multiple gear meshing. This design allows the motor to maintain high torque output at low speeds while reducing transmission errors.

2.Gear mesh optimization

Cycloidal pin wheel or planetary gear structure, with high precision eccentric bearings, to ensure the smoothness of gear meshing. The eccentricity of eccentric bearing directly affects the deceleration ratio, and different transmission ratios can be achieved by adjusting the eccentricity. Gear material is usually selected high strength alloy steel, the surface hardened treatment, wear resistance increased by more than 30%.

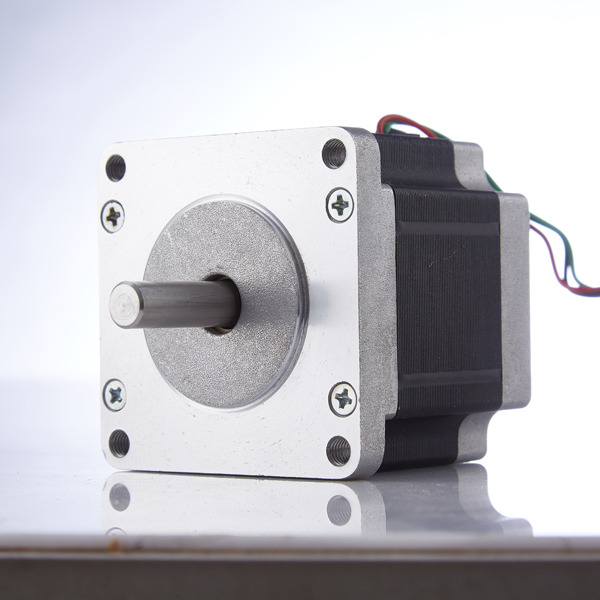

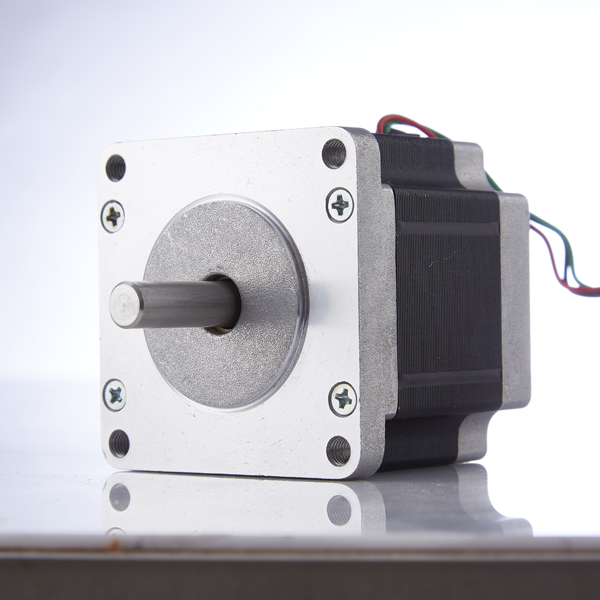

3.Modular design

The motor adopts unit modular structure, the core components include eccentric shaft, gear box, bearing seat, etc. Each module can be replaced independently. This design shortens maintenance time and reduces maintenance costs, especially for the needs of continuous production lines.

Second, performance advantage

1.High efficiency and energy saving

The transmission efficiency can reach more than 95%, which is 10%-15% higher than the traditional reducer. By optimizing the movement path of the eccentric shaft, the energy loss is reduced, and the power consumption is reduced by 20% under rated load.

2.Low noise operation

The gear meshing noise is less than 60 dB, the bearing adopts low noise design, and the vibration amplitude is less than 0.5mm/s. Precision machining gear surface roughness Ra≤0.8μm, further reduce the operating noise.

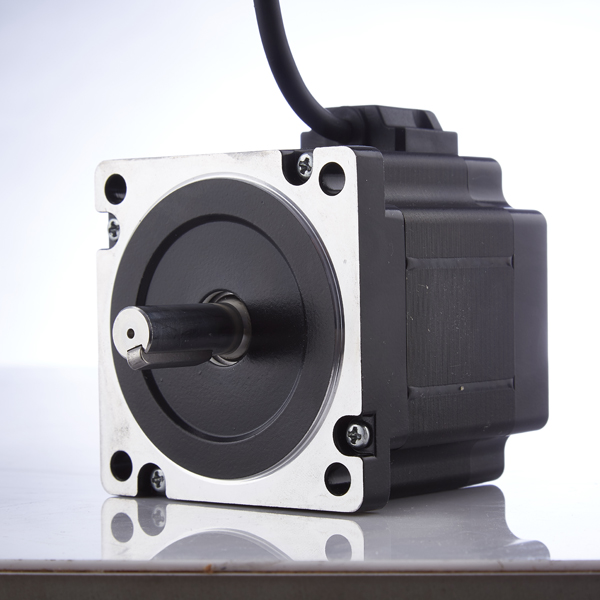

3.Compact and lightweight

The volume is reduced by 30% and the weight is reduced by 25% compared with the same power reducer. The integrated design of eccentric shaft and gear group reduces space occupancy and facilitates integration into equipment.

4.Long life design

The gear box adopts a forced lubrication system, and the lubricating oil flow is adjustable to ensure that the eccentric shaft and gear are fully lubricated. The bearing life is as long as 20,000 hours, the gear life is more than 10,000 hours, and the maintenance cycle is extended to more than 1 year.

Three, application fields

1.Industrial automation

In robot joints, CNC machine tools, packaging machinery, eccentric shaft gear motors provide precise speed and torque control. For example, in the joint drive of industrial robots, the repeated positioning accuracy can reach ±0.01mm.

2.Medical device

For surgical robots, CT scanners and other equipment, to meet the high precision, low noise requirements. The small vibration characteristics of the eccentric shaft gear motor ensure the stability of medical equipment in precise operation.

3.aerospace

In UAV steering gear and satellite attitude control system, its lightweight design and high reliability become the key. For example, the eccentric shaft reducer motor for the drone steering gear weighs only 50g, but it can output 2Nm of torque.

4.New energy field

Used in wind turbine rotor system, solar tracking device, adapt to harsh environment. The corrosion-resistant design of the eccentric shaft gear motor enables it to have a life of more than 15 years in seaside wind farms.

Fourth, development trend

1.Intelligent integration

In the future, sensors and controllers will be integrated to achieve real-time monitoring and adaptive adjustment. For example, through the torque sensor feedback, the movement parameters of the eccentric shaft are dynamically adjusted to optimize the transmission efficiency.

2.New material application

Ceramic bearings and carbon fiber composite gears are used to further improve performance. The friction coefficient of ceramic bearings is reduced by 50%, and the weight of carbon fiber gears is reduced by 40%.

3.Green manufacturing

The lubrication system is developed to be oil-free, using magnetic bearings or solid lubrication technology to reduce environmental pollution. At the same time, the recovery rate of motor materials has been increased to 90%, which meets the requirements of sustainable development.

4.Miniaturization breakthrough

With the development of MEMS technology, the size of eccentric shaft gear motor will be reduced to the millimeter level and applied to micro-robots, biomedical equipment and other fields