- Home

- About us

- Products

-

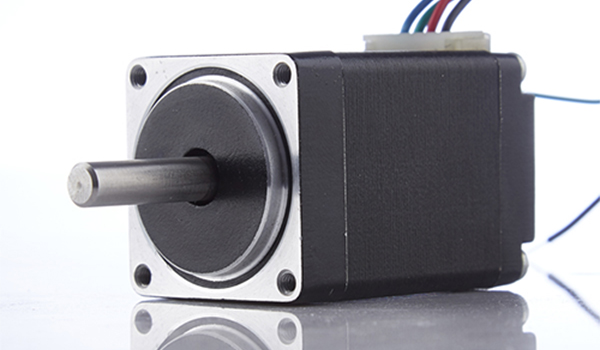

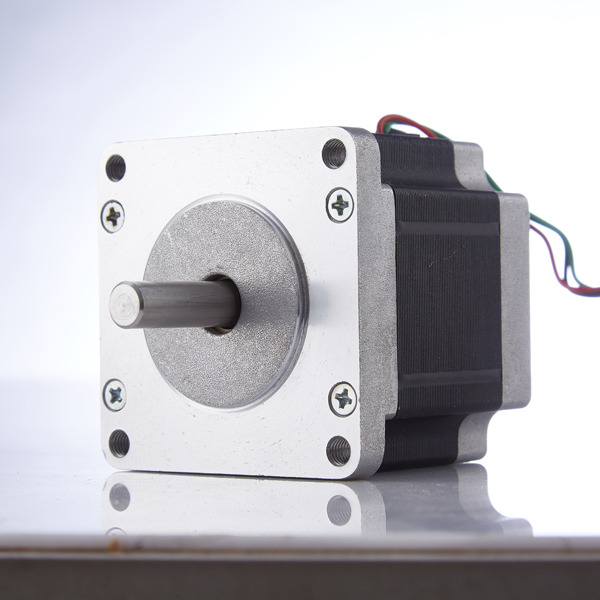

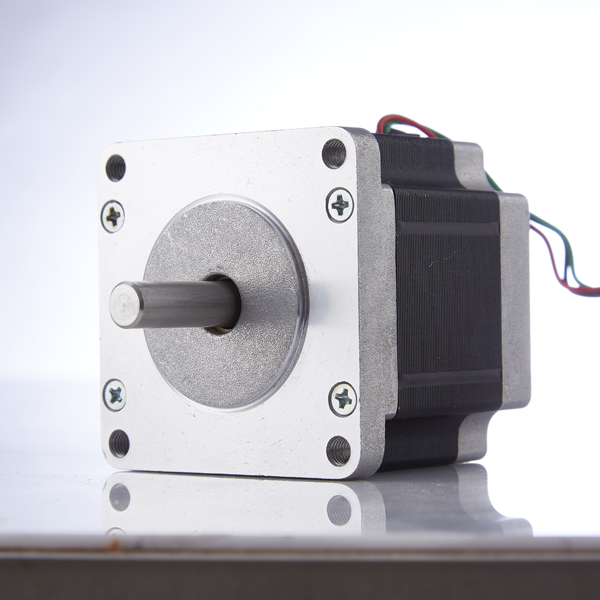

Stepper Motor Series Stepper motor, also known as pulse motor, is a motor that converts electrical pulse signals into corresponding angular displacement or linear displacement. Its unique working principle and wide range of applications make stepper motors occupy an important position in modern industrial control systems. See more

-

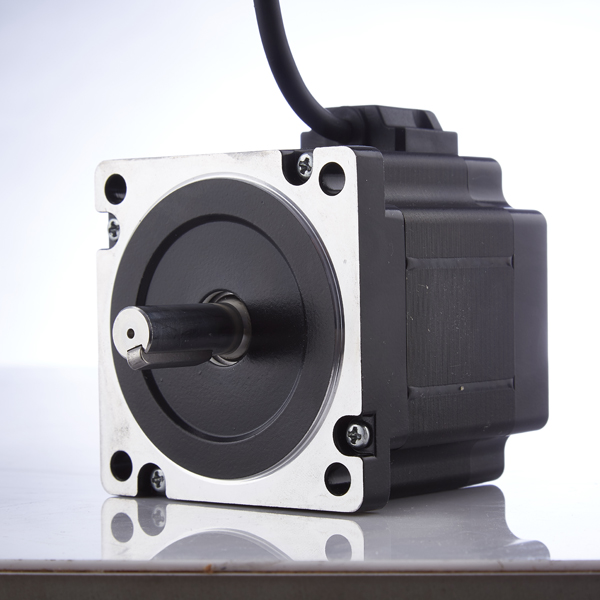

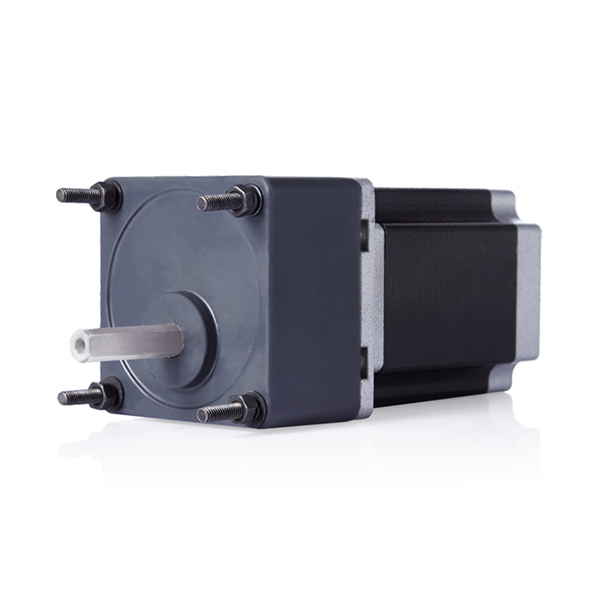

Special stepper motor series Special stepper motors, as a type of stepper motor, also have the ability to convert electrical pulse signals into corresponding angular displacement or linear displacement. However, they may have more unique or specialized designs in some aspects to meet specific application requirements. See more

-

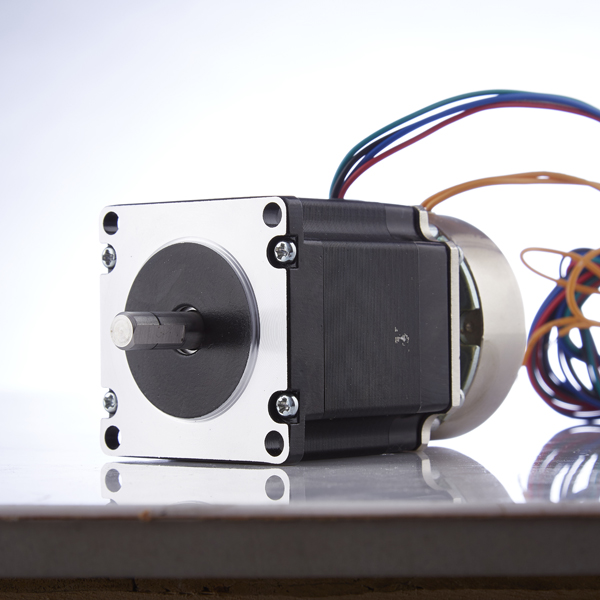

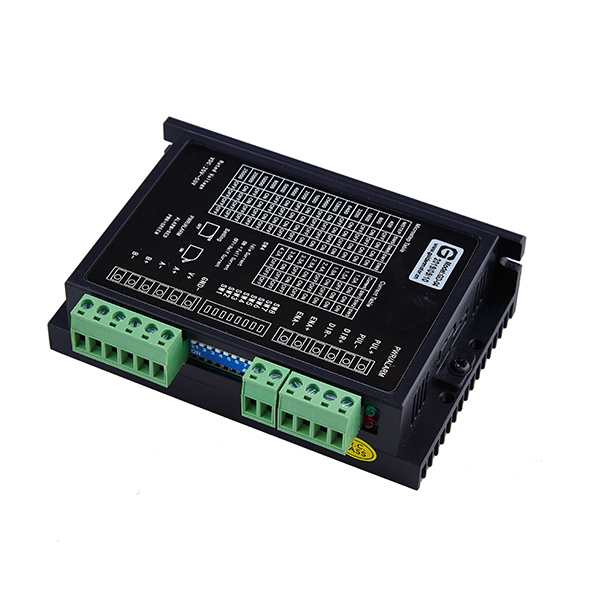

Driver Series Driver, in the application of stepper motor, specifically refers to the stepper motor driver, which is an actuator that converts electrical pulses into angular displacement. It receives pulse signals from the control system (such as PLC, computer, etc.)…… See more

-

- Application

- Video

- News

- Contact