From the conveyor belt for sorting express delivery, to the xyz axis platform for 3D printers, to the main joint drive for simulation robots, scenes of linear motion can be seen everywhere in daily life. Obviously, regardless of the implementation path, the power source is always the motor that inputs rotational motion. So, what are the solutions to convert rotational motion into linear motion? Let's take a quick look.

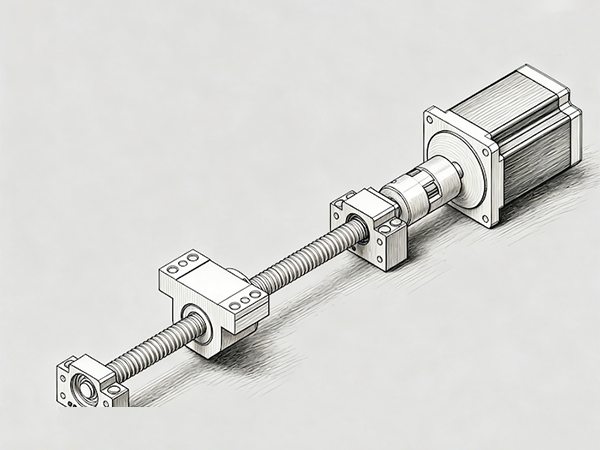

1、 Threaded transmission

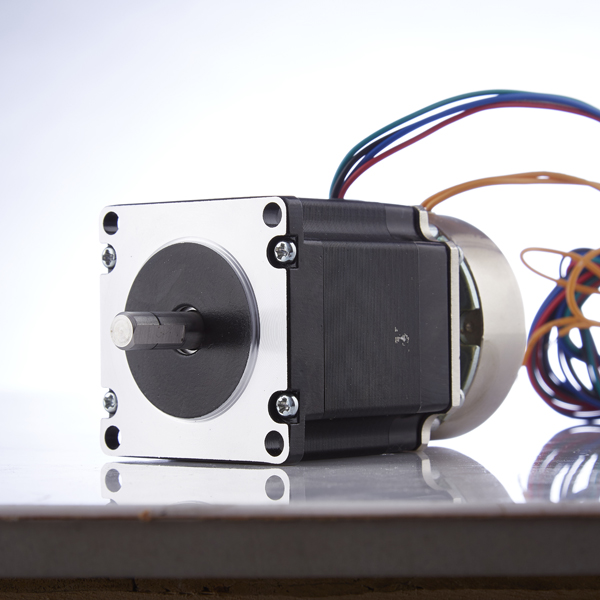

The most typical type of threaded transmission is the screw mechanism (Figure 1), and the screw may be the most widely used rounding and straightening scheme. Due to its rigid transmission characteristics, it is suitable for situations where large torque is transmitted or maintained. Screw mechanisms are divided into sliding screws and ball screws. The former has a simple and direct structure, low cost, self-locking properties, but low transmission efficiency, high wear, and average accuracy; The latter uses rolling friction of balls instead of sliding friction, greatly increasing transmission efficiency (over 90%) and high precision, but the mechanism is complex and the cost is high.

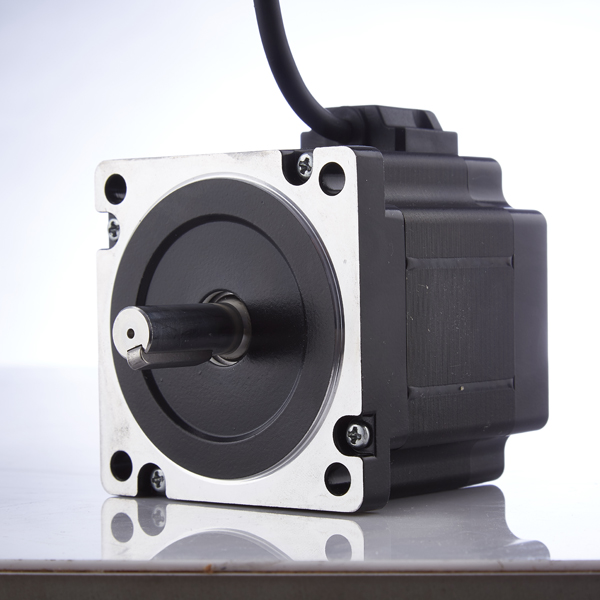

Figure 1 Motor driven screw drive system

Due to the excellent torque transmission capability and precision of the screw mechanism, sliding screws are mostly used for XYZ axis platforms, linear sliding tables, etc. For certain instruments and equipment that require high precision, ball screw mechanisms are used.

2、 Chain/belt drive

This type of mechanism is the simplest circular linear scheme, with a typical example being a synchronous pulley belt (Figure 2). The synchronous pulley belt is composed of a synchronous pulley and a synchronous belt. The synchronous pulley and the synchronous belt connected to the motor output shaft are connected through a tooth groove structure. This structure is easy to assemble, flexible, low-noise, and low-cost. When the load is not large, it can ensure good accuracy and synchronization. However, due to the low strength and certain elasticity of the belt, it cannot guarantee accuracy and reliability under high loads. The use of metal wire/high-strength woven material lining belts can greatly compensate for the defects of synchronous pulley belts, and has indeed become an increasingly popular choice for linear mechanisms.

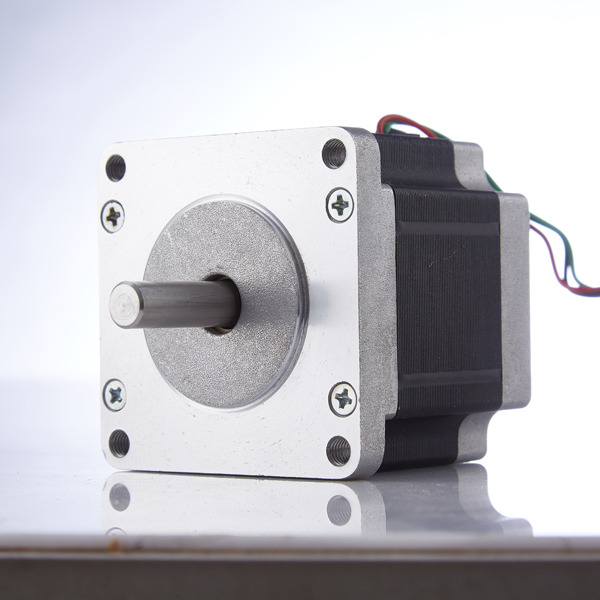

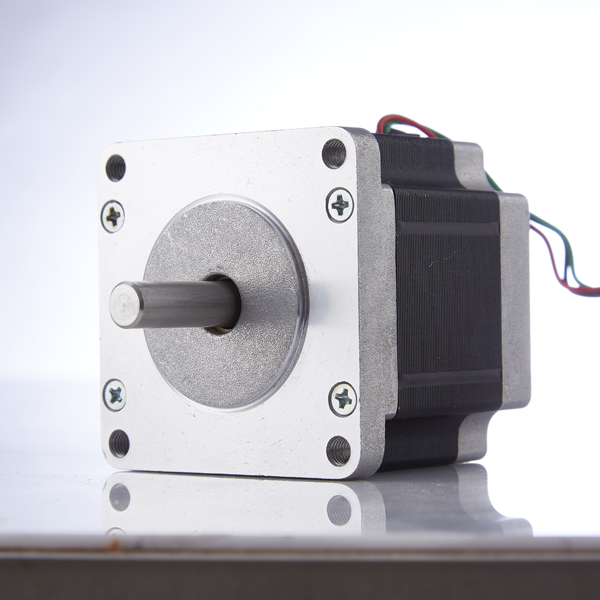

Figure 2 Motor driven synchronous wheel/belt system

3、 Gear and rack transmission

Gear and rack transmission is very similar to synchronous belt transmission, turning a soft belt into an iron object - a rack. Obviously, this structure is simple, reliable, rigid, and has a high load capacity. However, due to the characteristics of the gear structure, it has problems such as obvious wear and high noise.

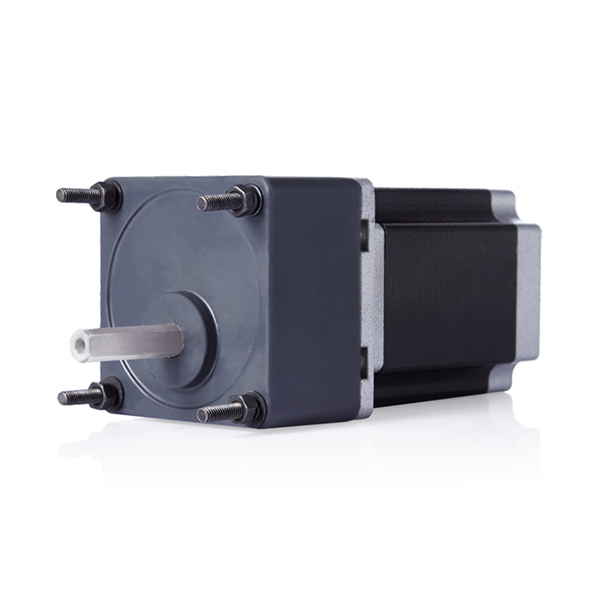

Figure 3 Motor driven gear/rack system

4、 Connecting rod, cam drive

The connecting rod and cam mechanism are classic reciprocating motion structures. As shown in Figure 4, the connecting rod transmission utilizes the rotation of the crank (eccentric wheel) to drive the slider to perform reciprocating linear motion through the connecting rod. The structure is simple and reliable, and can convert uniform rotation into non-uniform linear reciprocating motion, with strong load-bearing capacity. However, the load on the output shaft is uneven, and the linear motion of the output cannot control the speed and force, so it is limited to reciprocating motion situations with low requirements for speed and force control. The cylinder of an internal combustion engine uses a crank slider mechanism to convert reciprocating motion into circular motion.

Figure 4 Linkage slider mechanism

Cam transmission drives a cam with a specific profile to rotate through a motor, pushing the follower (tappet) to achieve precise and customized reciprocating linear motion. It can achieve very complex motion laws (such as stop lift stop lower), and is flexible in design. However, cam design and processing are complex, and it is prone to wear at high speeds, which limits its application scenarios。

Figure 5 Cam mechanism

The commonly used implementation paths for converting curves into straight lines have their own characteristics and advantages, and should be flexibly selected according to the application scenario.

In addition, using a linear motor can directly output linear motion. A general linear motor refers to the type of motor shown in Figure 6, which expands the traditional two-dimensional rotor stator structure into a one-dimensional linear structure, and drives the linear "rotor" to translate by controlling the magnetic field of the linear "stator", thereby achieving the effect of linear motion.

Figure 6 Linear motor

There is also a type of linear motor similar to the dynamic coil structure of a loudspeaker (Figure 7), called a "voice coil" motor. The structure is shown in Figure 8, and its principle is exactly the same as that of a loudspeaker. By controlling the current in the coil to control the magnitude and direction of the force on the coil, it outputs reciprocating linear motion.

Figure 7 Speaker principle

Figure 8 Structure of voice coil motor

Dongguan Jindi Motor Co., Ltd

Gold Motor Gold Quality

Golden Motor Golden Quality