The key points of repairing stepper motors involve multiple aspects, including troubleshooting, maintenance checks, and repair measures for specific problems. Here are some key maintenance points:

1、 Troubleshooting

Check the power supply:

Ensure that the power supply voltage is stable and meets the requirements of the motor.

Use a multimeter or other tools to measure the power supply voltage and current, and check for any abnormal fluctuations.

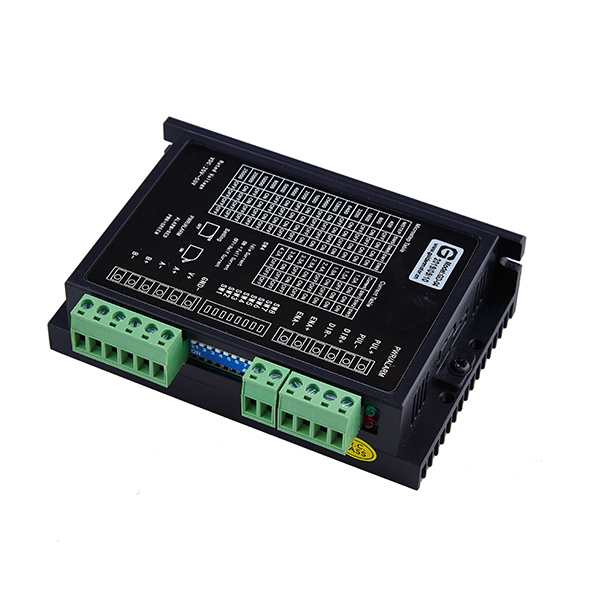

Check the drive:

Check if the driver is working properly, including whether the output signal is stable.

Driver failure may include issues such as unresponsive, unstable speed, excessive noise, overheating, high current, pulse loss, and direction control failure.

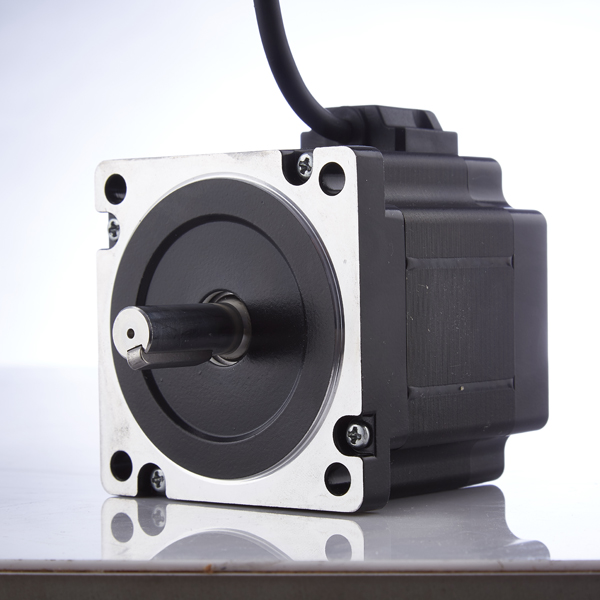

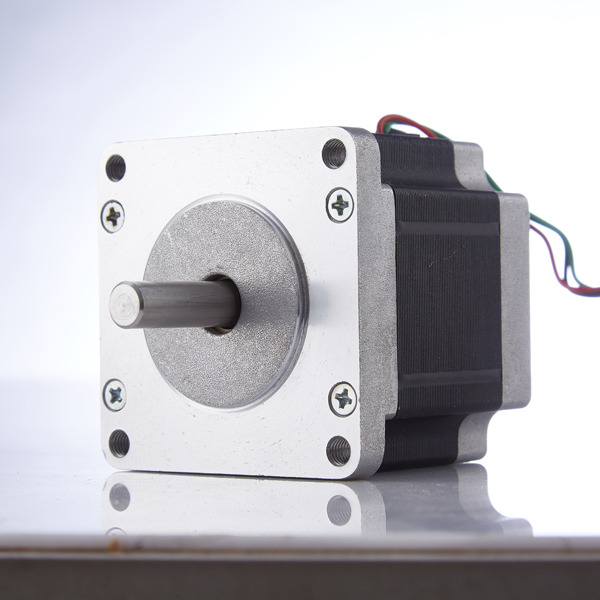

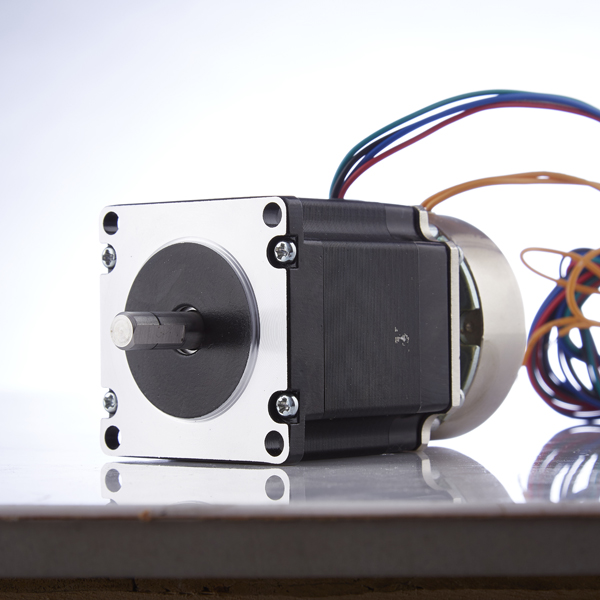

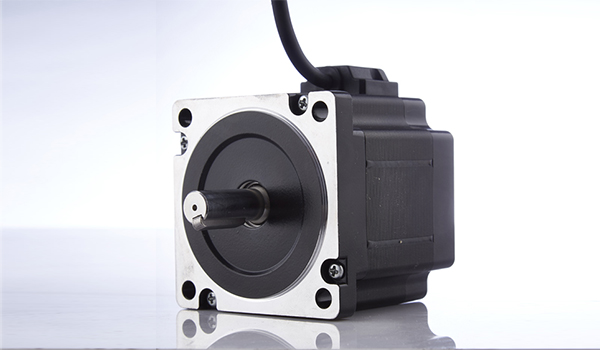

Check the motor itself:

Check if the motor coil is open, short circuited, or if the rotor is faulty.

Use a multimeter or other tools to measure the resistance, insulation resistance, and other parameters of the motor.

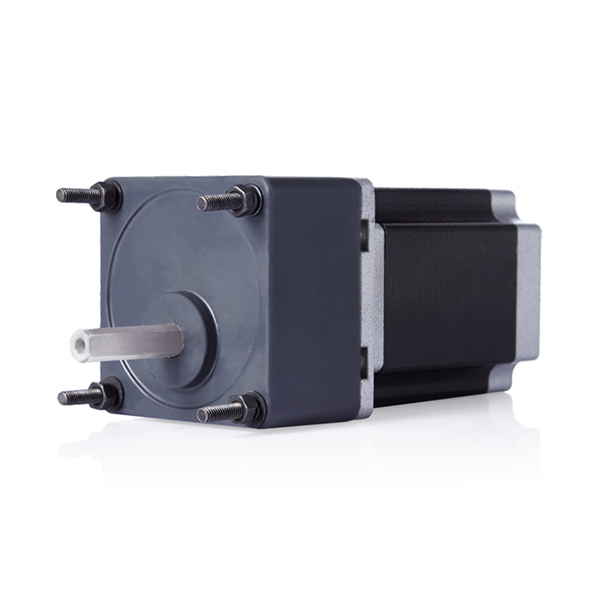

Check the mechanical device:

Check if the mechanical device connected to the stepper motor is normal, including the transmission device, bearings, etc.

Mechanical device jamming, loosening, and other issues may affect the normal operation of the motor.

2、 Maintenance inspection

Regular inspection of motors and drivers:

Regularly check the wear of motor bearings and gears.

Check whether the connection between the motor and the driver is good, including whether the wiring is firm, whether the plug is loose, etc.

Check if the driver parameter settings are correct, including current, voltage, fineness, etc.

Regular cleaning:

Regularly clean the motor and driver casing to avoid the accumulation of dust and dirt that may affect heat dissipation and performance.

Avoid using chemical cleaners or water during cleaning to prevent damage to the internal components of the motor.

Pay attention to the usage environment:

Avoid using the motor in harsh environments such as humidity, high temperature, and high humidity.

Avoid mechanical shock and vibration to ensure the stability and reliability of the motor.

3、 Repair measures

Replace damaged components:

Damaged components such as power supplies, drivers, motor coils, etc. should be replaced in a timely manner to ensure the normal operation of the motor.

Adjust parameters:

Adjust the current, voltage, and other parameters of the driver according to the actual situation to match the load and performance requirements of the motor.

Repair mechanical device:

For mechanical problems such as stuck transmission devices or loose bearings, they should be repaired or replaced in a timely manner.

Strengthen heat dissipation:

For overheating issues, it is possible to strengthen the motor's heat dissipation measures, such as adding heat sinks, fans, etc.

Avoid overload:

During use, motor overload operation should be avoided to prevent damage to the motor and driver.

4、 Precautions

safety first:

When repairing a stepper motor, be sure to cut off the power and follow the relevant safety operating procedures.

Professional maintenance:

For complex maintenance tasks or uncertain operations, it is recommended to seek professional assistance.

Record the repair process:

Record the key steps and issues discovered during the maintenance process for future reference and summary of experience.

In summary, the key points of repairing stepper motors include troubleshooting, maintenance checks, repair measures, and precautions. Through meticulous repair and maintenance work, the stable operation and extended service life of stepper motors can be ensured.