Stepper motors and servo motors have significant differences in multiple aspects, mainly reflected in accuracy, control mode, feedback mode, torque, speed, torque frequency characteristics, overload characteristics, encoder type, response speed, vibration resistance, temperature rise, and price. Here is a detailed analysis of these differences:

1. Accuracy

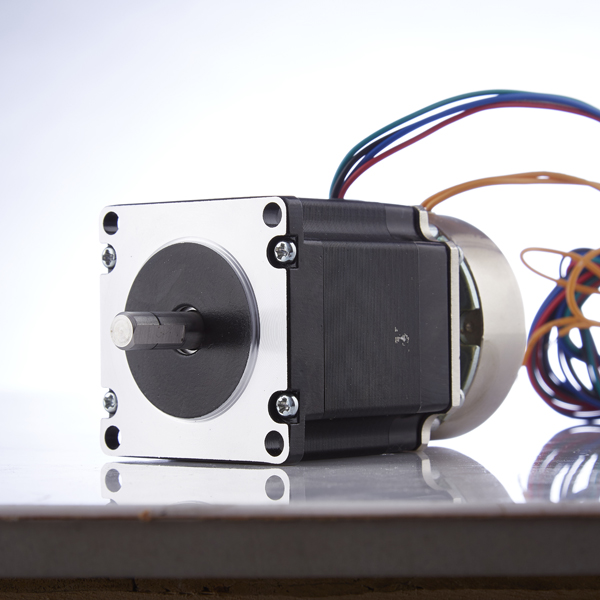

Stepper motor: Generally, its accuracy is low and mainly depends on the step angle. Although it can accurately control each step angle, it cannot monitor position errors in real time and make corrections. Therefore, there may be accumulated errors in long-term operation or complex applications.

Servo motor: High precision, as it relies on pulses for positioning, one rotation corresponds to one pulse, and the accuracy can reach 0.001mm. Servo motors monitor real-time parameters such as position and speed through feedback devices (such as encoders), and dynamically adjust control signals based on feedback signals to achieve more accurate position control.

2. Control mode

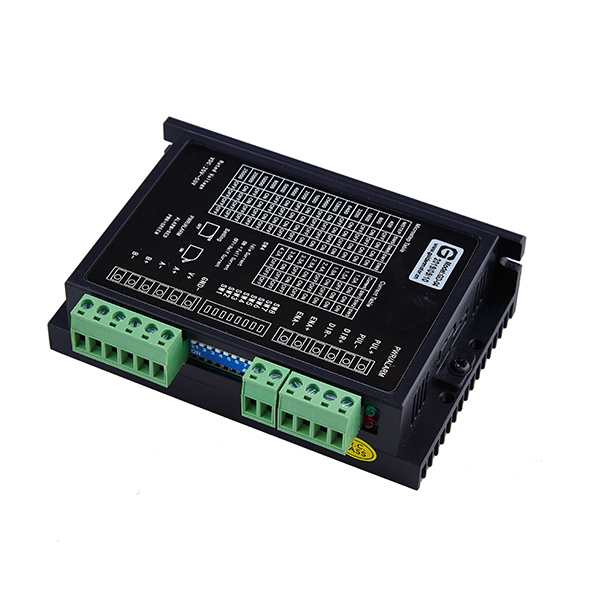

Stepper motor: It adopts position, speed, and torque control, usually open-loop control or connected encoder feedback to prevent step loss.

Servo motor: The information detected by the encoder is fed back to the controller to control the position, and closed-loop control is adopted to more accurately control the operating status of the motor.

3. Feedback method

Stepper motor: for open-loop control or encoder feedback to prevent step loss, without real-time position feedback mechanism.

Servo motor: For closed-loop control, only encoder feedback can be used, which can monitor and adjust the position and speed of the motor in real time.

4. Torque

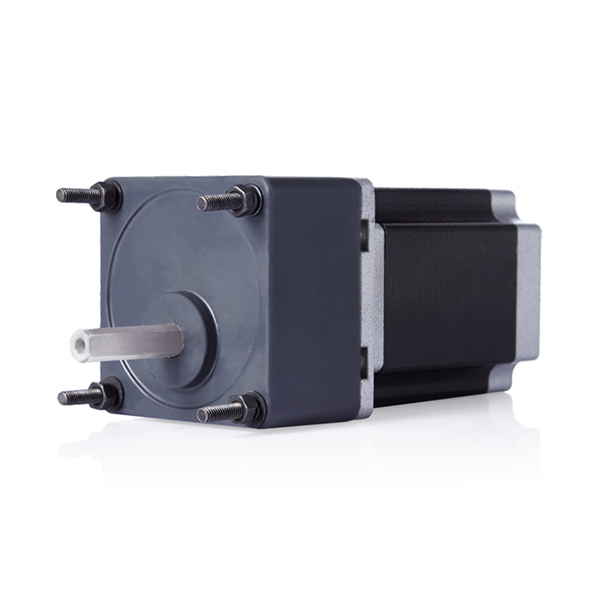

Stepper motor: The torque is generally below 40Nm, suitable for low torque applications.

Servo motor: capable of achieving a full range of torque, suitable for applications with high torque and high dynamic performance.

5. Speed

Stepper motor: The speed is relatively low, generally less than 2000rpm, and only produces high torque at low speeds.

Servo motor: High speed, among which DC servo motor can reach 20000rpm, with constant torque output, can generate high torque at both high and low speeds.

6. Moment frequency characteristics

Stepper motor: The torque decreases as the speed increases, and the torque decreases extremely rapidly at high speeds.

Servo motor: With good torque frequency characteristics, it can maintain high torque output during high-speed operation.

7. Overload characteristics

Stepper motor: Generally, it does not have overload capacity and may experience step loss when overloaded.

Servo motor: has strong overload capacity, can withstand 3-10 times overload, and can better cope with sudden load changes.

8. Encoder type

Stepper motor: No encoder is required when in open-loop state.

Servo motor: usually uses photoelectric encoders or other high-precision encoders.

9. Response speed

Stepper motor: Slow response speed.

Servo motor: Fast response speed, able to respond faster to changes in control signals.

10. Vibration resistance

Stepper motor: Good vibration resistance, suitable for use in environments with high vibration.

Servo motor: Poor vibration resistance, sensitive to vibration.

11. Temperature rise

Stepper motor: There is a significant temperature rise during operation.

Servo motor: The temperature rise is not significant during operation, but the heat dissipation performance is good.

12. Price

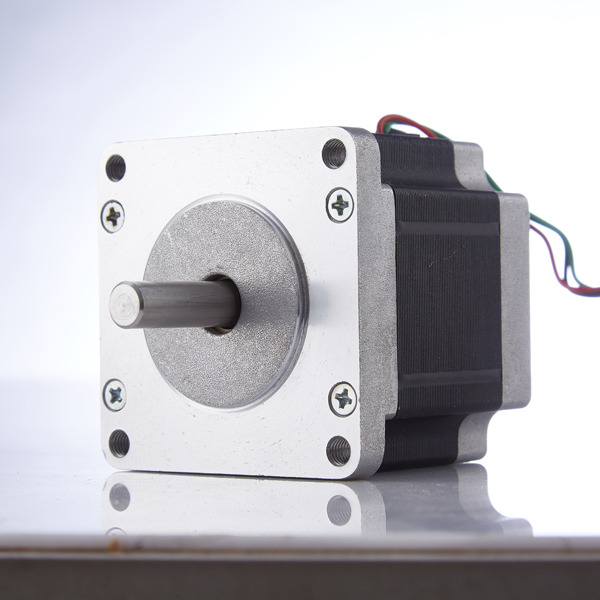

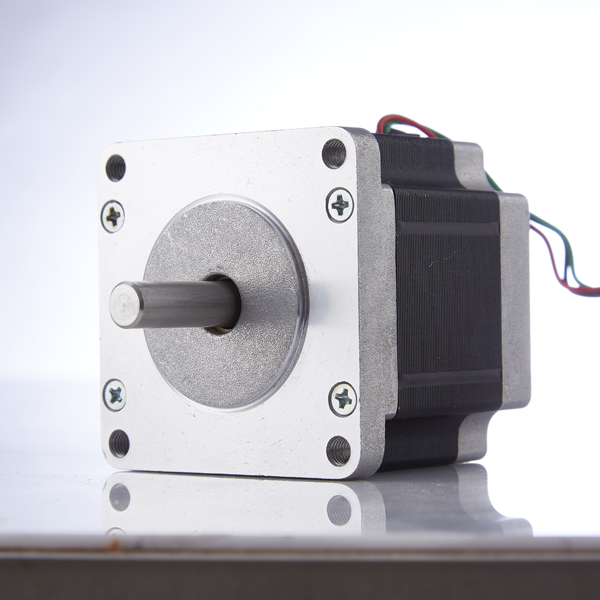

Stepper motor: Low cost, suitable for cost sensitive application scenarios.

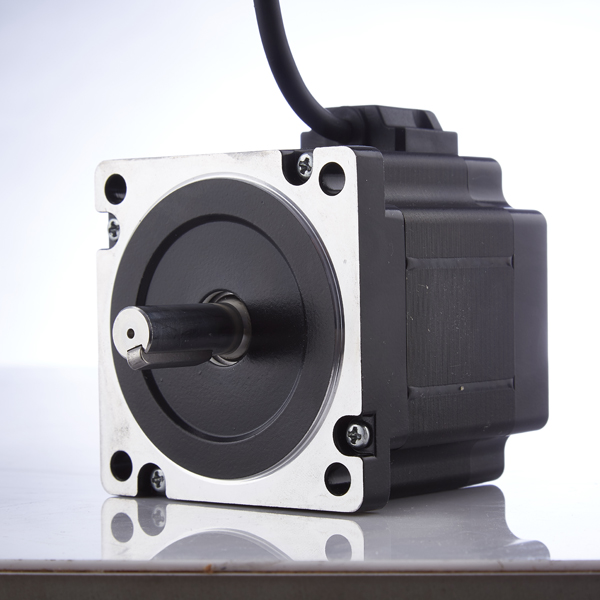

Servo motor: expensive, requiring the use of rotary encoders and servo drives, but with superior performance.

application area

Stepper motor: Due to its low cost and simple control, it is widely used in industrial automation, aerospace, medical equipment, 3D printing and other fields, suitable for applications with low precision requirements and cost sensitivity.

Servo motor: Due to its high precision, high response speed, and high overload capacity, it is widely used in high-precision equipment such as machine tools, laser cutting machines, injection molding machines, as well as automation production lines, robotics technology, medical equipment, aerospace and other fields. It is suitable for application scenarios that require high precision and dynamic performance.

In summary, there are significant differences between stepper motors and servo motors in multiple aspects, and the choice of motor depends on the specific application scenario and requirements.